A Guide to Choosing a Fly Line for Single-Handed Rods

Single-Handed Rod Fly Lines

Choosing the correct fly line is key to success in fly fishing – your rod and line must work together harmoniously to make casting easy and pleasurable. In fact, you could argue your fly line is the single most important tackle item in your set up. It’s no accident that certain fly lines perform well with particular rods giving the outfit a sweet, easy casting feel that makes time spent by the water a real pleasure. If you are unsure of which line to choose, our expert advisors can help and recommend a line that will be suited to your fishing and compliment your rod.

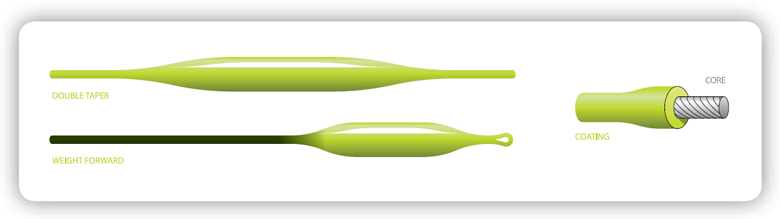

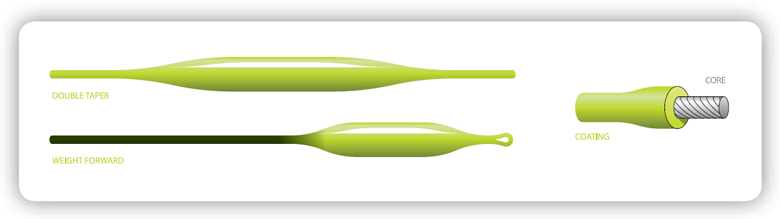

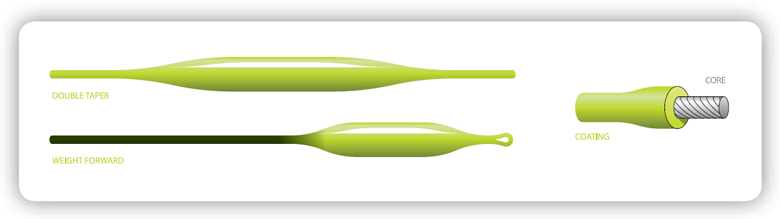

Let’s look at the construction of a fly line and explain some of the jargon used along the way.

What’s a fly line made of?

There are two components that make up a fly line:-

- The core – this is the inner part of the line that determines how strong the line is, as well as how stretchy and how stiff it will be. The cores of most lines are made of braided nylon or nylon monofilament in some cases. Lines need to be stronger than the heaviest tippet that you are likely to use, so a trout line will break at around 20lbs and at the other extreme lines designed for big game fishing will break at around 70lbs. Fly lines need to stretch a little so they remain supple – if all the stretch is removed they can have ‘memory’ problems (the line stays in loose coils when pulled off the reel). To cast well, lines also need to be stiff enough to hold loop shapes in the air when you cast – the stiffness of a line is controlled by the nature of the core and the properties of the plastic used in the coating. Specialist lines for use in tropical conditions feel stiff and wiry in our UK temperate climate but come into their own as temperatures increase.

- The coating – the plastic formula used for the lines coating and how it is bonded to the core will determine how the line behaves on the water. Also, the thickness and density will give the correct casting weight to adequately load your rod. The exact weight is calculated to fit with the AFTM scale – so your can choose a 6 weight line that you know will load your 6 weight rod perfectly. The density of the coating will determine whether the line will float or sink. Floating lines have tiny micro balloons incorporated into the plastic to ensure the line will float at all times and may also incorporate a hydrophobic chemical to repel water. Treated this way the line will always float high in the water without any further dressing. Sinking lines have powdered tungsten in their coating in measured amounts to give a range of sink rates from 1 to 8 inches per second. Colour is provided by pigment added to the plastic mix.

Tapers

To cast well and give good presentation fly lines are tapered, the taper determines how energy will travel through the line and how efficiently it will move through the air during casting. There are two basic tapers used - the most popular by a country mile are weight-forward tapers (WF). The other option is a double-taper (DT). DT’s are still used by some river trout anglers for delicate presentation but the huge development in WF lines has rendered them virtually obsolete in other areas of the sport with demand shrinking year on year.

Here is the anatomy of a typical weight forward fly line:-

- Tip – this is the section the leader is attached to and may have a loop built into it for this purpose, it is short 6-12 inches to allow for trimming to fit new braided loops etc without eating into the tapered section.

- Front Taper – This section of fly line increases in diameter as it gets further from the tip, it will generally be 4’ to 8’ long. The longer, finer and more gently it tapers the more delicately the fly will be delivered, but a line that allows delicate presentation will perform poorly with large flies or casting into an awkward wind.

- Belly – This thicker section of fly line is the line’s engine room. It is also the longest part of the taper that transmits the full energy of the cast.

- Rear taper – Here the line reduces in diameter again. Good design here will greatly influence how smoothly the line will cast.

- Head Length – this term describes the tapered section (front taper, belly and rear taper) of a fly line.

- Running line – This thinner final section attaches to the backing on the reel and by virtue of its light weight and narrow diameter is easily carried by the head when you shoot line in the final stage of a cast.

Guide by Sportfish expert Allan Shephard AAPGAI

Still need help?

For more help and information on purchasing your new fly line for a single-handed rod please contact Sportfish on 01544 327111 or email danny.north@sportfish.co.uk

Single-Handed Rod Fly Lines

Choosing the correct fly line is key to success in fly fishing – your rod and line must work together harmoniously to make casting easy and pleasurable. In fact, you could argue your fly line is the single most important tackle item in your set up. It’s no accident that certain fly lines perform well with particular rods giving the outfit a sweet, easy casting feel that makes time spent by the water a real pleasure. If you are unsure of which line to choose, our expert advisors can help and recommend a line that will be suited to your fishing and compliment your rod.

Let’s look at the construction of a fly line and explain some of the jargon used along the way.

What’s a fly line made of?

There are two components that make up a fly line:-

- The core – this is the inner part of the line that determines how strong the line is, as well as how stretchy and how stiff it will be. The cores of most lines are made of braided nylon or nylon monofilament in some cases. Lines need to be stronger than the heaviest tippet that you are likely to use, so a trout line will break at around 20lbs and at the other extreme lines designed for big game fishing will break at around 70lbs. Fly lines need to stretch a little so they remain supple – if all the stretch is removed they can have ‘memory’ problems (the line stays in loose coils when pulled off the reel). To cast well, lines also need to be stiff enough to hold loop shapes in the air when you cast – the stiffness of a line is controlled by the nature of the core and the properties of the plastic used in the coating. Specialist lines for use in tropical conditions feel stiff and wiry in our UK temperate climate but come into their own as temperatures increase.

- The coating – the plastic formula used for the lines coating and how it is bonded to the core will determine how the line behaves on the water. Also, the thickness and density will give the correct casting weight to adequately load your rod. The exact weight is calculated to fit with the AFTM scale – so your can choose a 6 weight line that you know will load your 6 weight rod perfectly. The density of the coating will determine whether the line will float or sink. Floating lines have tiny micro balloons incorporated into the plastic to ensure the line will float at all times and may also incorporate a hydrophobic chemical to repel water. Treated this way the line will always float high in the water without any further dressing. Sinking lines have powdered tungsten in their coating in measured amounts to give a range of sink rates from 1 to 8 inches per second. Colour is provided by pigment added to the plastic mix.

Tapers

To cast well and give good presentation fly lines are tapered, the taper determines how energy will travel through the line and how efficiently it will move through the air during casting. There are two basic tapers used - the most popular by a country mile are weight-forward tapers (WF). The other option is a double-taper (DT). DT’s are still used by some river trout anglers for delicate presentation but the huge development in WF lines has rendered them virtually obsolete in other areas of the sport with demand shrinking year on year.

Here is the anatomy of a typical weight forward fly line:-

- Tip – this is the section the leader is attached to and may have a loop built into it for this purpose, it is short 6-12 inches to allow for trimming to fit new braided loops etc without eating into the tapered section.

- Front Taper – This section of fly line increases in diameter as it gets further from the tip, it will generally be 4’ to 8’ long. The longer, finer and more gently it tapers the more delicately the fly will be delivered, but a line that allows delicate presentation will perform poorly with large flies or casting into an awkward wind.

- Belly – This thicker section of fly line is the line’s engine room. It is also the longest part of the taper that transmits the full energy of the cast.

- Rear taper – Here the line reduces in diameter again. Good design here will greatly influence how smoothly the line will cast.

- Head Length – this term describes the tapered section (front taper, belly and rear taper) of a fly line.

- Running line – This thinner final section attaches to the backing on the reel and by virtue of its light weight and narrow diameter is easily carried by the head when you shoot line in the final stage of a cast.

Still need help?

For more help and information on purchasing your new fly line for a single-handed rod please contact Sportfish on 01544 327111 or email sportfish@sportfish.co.uk